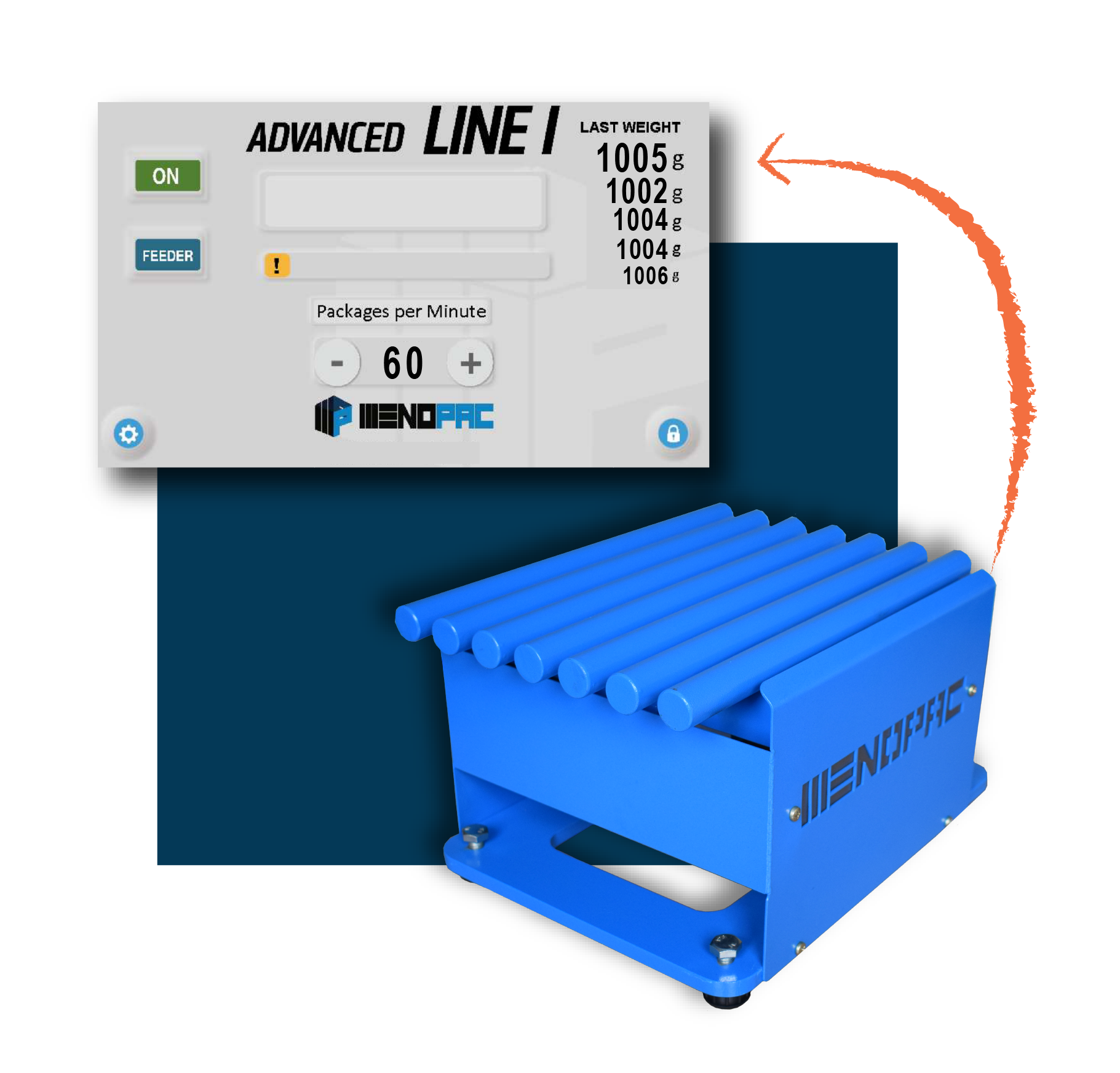

– Best cost-benefit, as our system is placed in the machine directly from the factory, using the same PLC, HMI, electrical and pneumatic components of the machine itself.

– Monitor and control the weights of the packages.

– Possibility of connecting the system to a stock control and material produced in your company and feeding your stock in real time, generating accurate reports.

– System for expelling packages that exceed pre-established limits. – Automatic adjustment of dosers, avoiding product waste.

– Best cost-benefit, as our system is placed in the machine directly from the factory, using the same PLC, HMI, electrical and pneumatic components of the machine itself. While other external systems, which are placed after the machine is manufactured, need a PLC, HMI, electrical and pneumatic components, which work independently, which increases the cost.

– Monitor and control the weights of the packages carried out on the packaging machine screen. – Possibility of connecting the system to a stock control and material produced in your company and feeding your stock in real time, generating accurate reports.

– System for expelling packages that exceed pre-established limits. – Automatic adjustment of dosers, avoiding product waste.

– Common spare parts, they do not need a huge range of specific parts for each equipment, both the packing and the baling machine have the same spare parts. This facilitates maintenance and reduces costs.

– Each baler can be fed by two wrappers, increasing productivity.

– Centralized technical support for the entire production line.

– Non-dedicated components are commercial, so they are easily found for replacement in the market.