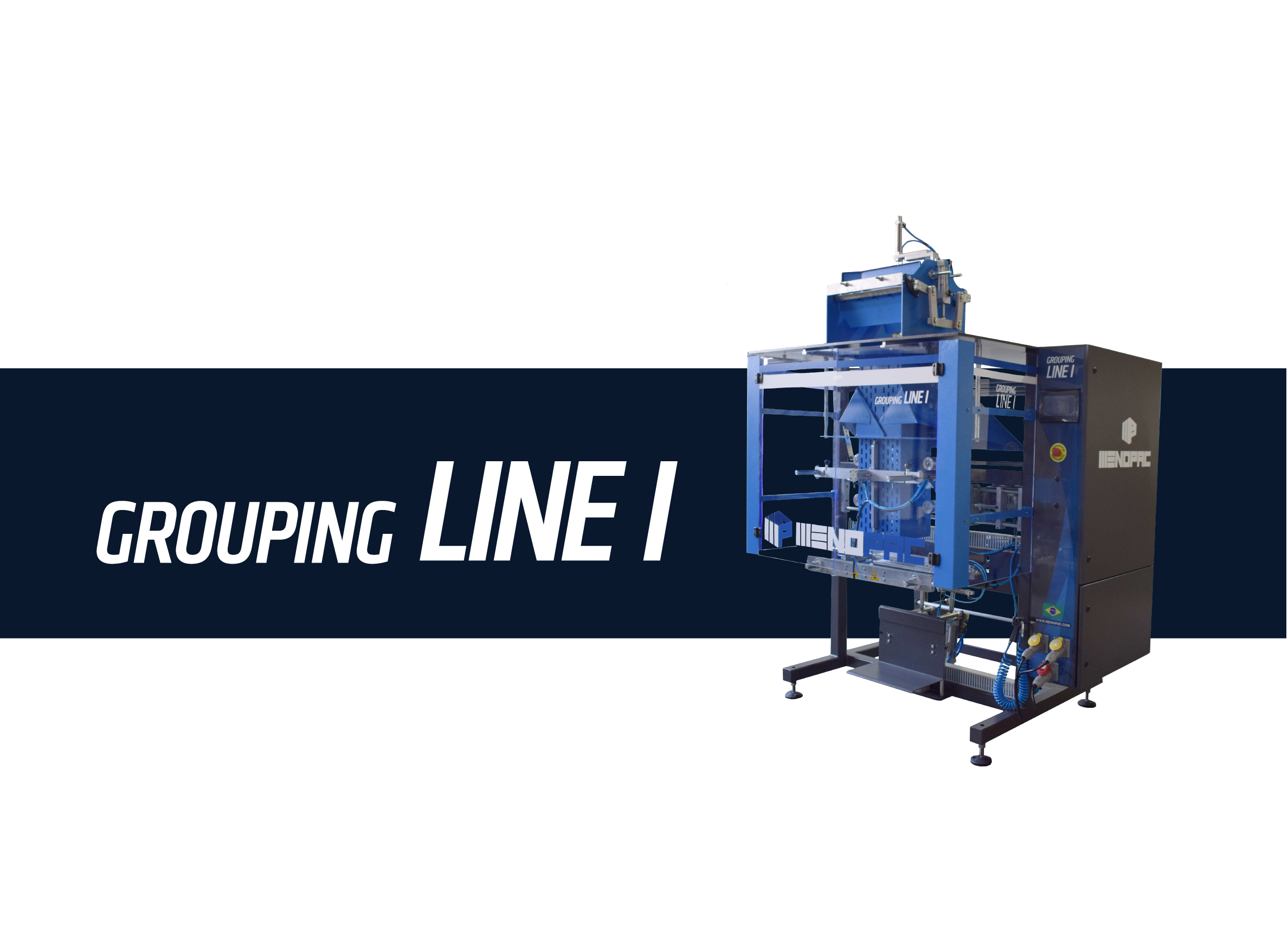

Equipment developed for grouping packages into a larger package (bale formation). You can set it to have the desired number of packages and columns. It can be fed by two packers simultaneously.

See some basic general features of the baler below:

| Controller sensor that indicates the end of the plastic coil on the operation panel

| Mechanical system that does not require lubrication, as per ISO standard

| Pneumatic system with cylinder rods made of stainless steel

| 304 stainless steel forming tube

| Reduction motor driven plastic coil unwinding system

| Fixed film traction system controlled by a frequency inverter and driven by a geared motor

| Ready bale conveyor belt

| 8mm acrylic front closing door

| Safety sensor for clamp that inhibits knife activation if the cycle is not completed

| Vibra-stop feet for equipment support and level adjustment on the floor

| Tubular carbon steel frame with high strength gray epoxy paint

| Controls and adjustments of equipment functions through PLC

| Standards and safety according to NR12

| With dispenser to form bales of one, two and three columns